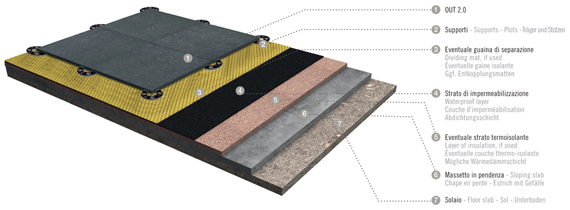

Easy Install Raised Flooring with Supports

In any situation where you need a floor that can easily be taken up for inspection purposes, the raised installation of OUT 2.0 on polypropylene supports is an excellent solution. This type of tiling is known as a “dry” solution as there is no need for adhesives or grout, making for a surface that is very fast to fit and can be put into service immediately. It is the ideal solution for tiling waterproof floor surfaces. The gap that is created between the floor’s upper surface and the sub-floor is useful as a solution to conceal the wiring for lighting systems or irrigation pipework, which can easily be inspected at any time by simply lifting up the slab.

Applications of Raised Floors:

- Outdoor public areas

- Verandas

Raised Flooring Benefits

- Dry installation is easy and fast, without the need for adhesives or grouts.

- Areas that are sloping or not level can be corrected.

- The slabs can be taken up and used again for other applications.

- Concealed pipework and wiring can be inspected immediately.

- Easy to clean and stain resistant.

Technical Guide

Refin recommends careful analysis of the intended use of the floor to ensure the best method is used to fit the floor based on the specific demands. For raised installation Ceramiche Refin recommends always the maximum height of 2 cm.

How to tile

- Place the OUT 2.0 on top of the supports laid out earlier.

- Check the surface is level.

The layers used depend on the type of application of the product: Refin recommends checking the specific standards that apply in your country to ensure the flooring is fitted correctly. Considering that porcelain stoneware is completely waterproof, the flooring must be provided with an appropriate slope for the conditions in which it is to be used, to allow rainwater to drain away. Nevertheless, as a result of the surface tension of the water, a film of water may remain on the surface for a few hours before evaporating. Should liquid remain on the surface, it is recommended to push it towards the grout lines using a floor brush or remove it with a wet and dry vacuum cleaner.

The layers used depend on the type of application of the product: Refin recommends checking the specific standards that apply in your country to ensure the flooring is fitted correctly. Considering that porcelain stoneware is completely waterproof, the flooring must be provided with an appropriate slope for the conditions in which it is to be used, to allow rainwater to drain away. Nevertheless, as a result of the surface tension of the water, a film of water may remain on the surface for a few hours before evaporating. Should liquid remain on the surface, it is recommended to push it towards the grout lines using a floor brush or remove it with a wet and dry vacuum cleaner.

Recommendations for dry installation

If the application of the 20 mm slabs foresees the ceramic product used in structural installations, the project engineer and/or customer must carefully assess the project requirements with regard to the technical specifications of the slabs. To prevent the risk of damage or injury, the manufacturer recommends:

- With regard to a raised floor installation a ceramic slab may fracture on impact if a heavy object falls on it from any significant height. Therefore the manufacturer recommends to check the specific intended use before starting the installation and to follow table for raised installation provided below. In certain conditions, reinforcing must be applied on the back of the slabs (mesh plus or galvanized steel sheet) supplied by the manufacturer;

- With reference to any dry installation system of flooring above the ground level, the manufacturer recommends to comply with local regulations and conditions of use with regard to wind-load, loadbearing, seismic events, etc.

Failure to comply with these recommendations may lead to improper use of the product and could cause serious damage or injury.

NOTE: For any detail and technical specication concerning the ber mesh plus or the galvanized steel sheet, please contact Ceramiche Refin . Ceramiche Refin is responsible only if it supplies the whole system (tile + ber mesh plus or galvanized sheet). Ceramiche Refin cannot be held responsible for reinforcing systems that has not supplied. In case ofbreakage, tile must be replaced immediately.

Edging Solutions

Should it be necessary to close one or more sides of the raised floor to conceal its structure, Refin recommends using a strip cut on site to the height needed. This strip can be glued to a metal L-shaped fixture, readily available on the market, and secured by inserting one side of it under the supports.

WARNING

If the application of the 20 mm slabs foresees the ceramic product used in structural installations, the project engineer and / or customer must carefully assess the project requirements with regard to the technical specifications of the slabs. To prevent the risk of damage or injury, the manufacturer recommends:

• With regard to a raised floor installation a ceramic slab may fracture on impact if a heavy object falls on it from any significant height. Therefore the manufacturer recommends to check the specific intended use before starting the installation. In certain conditions, reinforcing must be applied on the back of the slabs (mesh plus or galvanized steel sheet) supplied by the manufacturer;

• Outdoor pavings installed unglued above the ground level are subject to the action of the wind, with the risk, in some cases, of becoming airborne. The manufacturer recommends to require the assistance of a qualified professional in order to check the suitability of the installation system above the ground adopted, in accordance with the local laws and regulations and the conditions of use. Failure to do so could result in serious injury or property damage;

• With reference to any dry installation system of flooring above the ground level, the manufacturer recommends to comply with local regulations and conditions of use with regard to wind-load, loadbearing, seismic events, etc.

Failure to comply with these recommendations may lead to improper use of the product and could cause serious damage or injury.